Categories

Brand:

S4AItem NO.:

BL-C2001B(LED)Electric Dropbolt Lock 12V with fail-safe and LED Indicator

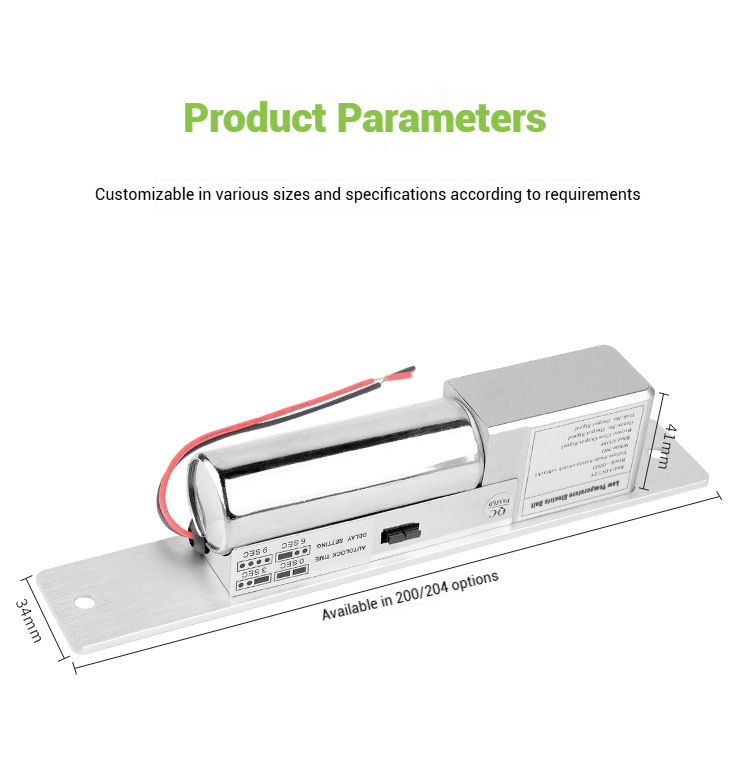

| Product name | 2 Line Electric Bolt Lock With Low Temperature And Timer/LED |

| Product model | BL-C2001B(LED) |

| Lock body size | 200/204 * 34 * 41mm(Default is 200mm) |

| Lock core size | 15mm diameter, 15mm extension length |

| input voltage | DC12V/DC24 input |

| Starting current | 500mA |

| Working current | 450mA |

| Withstand grip | 1000KG |

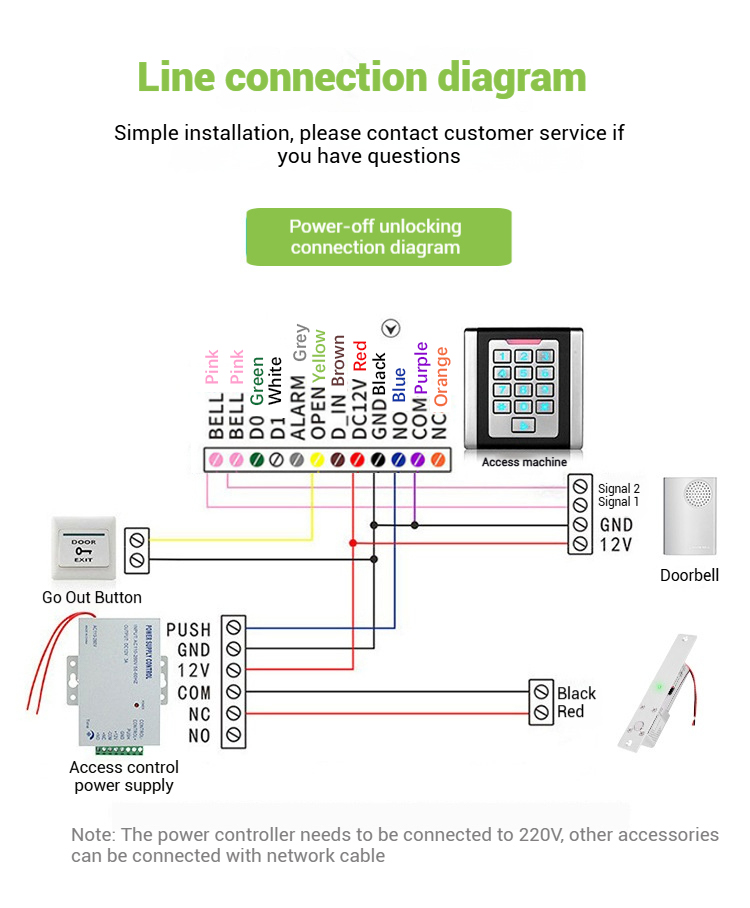

| Working mode | Power off unlocking, power on locking |

| Single lock weight | 0.65KG |

| performance testing | 500000 aging tests passed |

| Applicable door type | Wooden doors/glass doors/fire doors/metal doors |

Electric bolt locks and magnetic locks (electromagnetic locks) have distinct technical characteristics and application scenarios.

The advantages of electric bolt locks over magnetic locks are mainly reflected in security, installation flexibility, and functional adaptability.

Here is a detailed comparison: