Categories

Brand:

S4AItem NO.:

DL-150100-150kg Hydraulic Automatic Door Closer for Wooden Door

| Product Parameter | Parameter Description |

| S4A Model | DL-150 |

| Product Name | Super Door Closer |

|

|

|

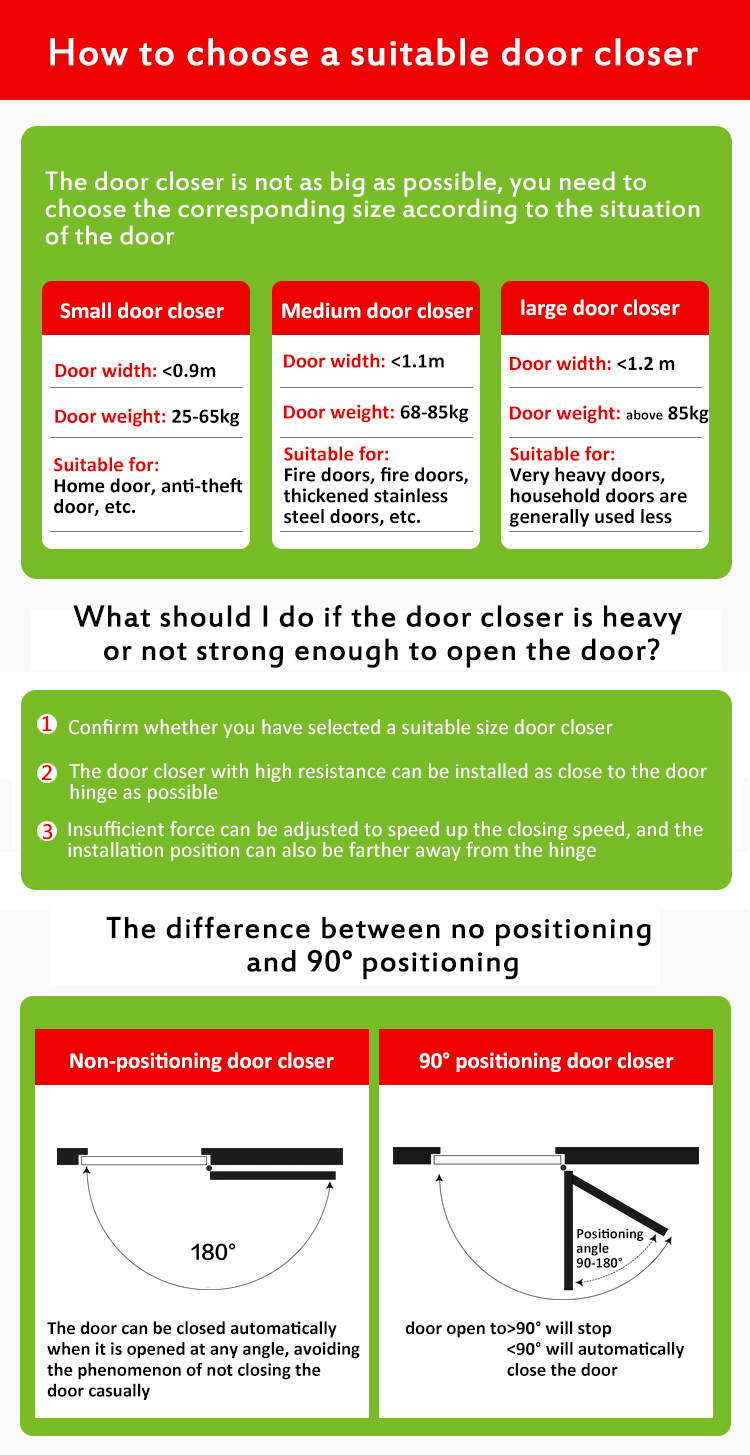

| Width of door max | 900-1100mm |

| Weight of door max | 100-150KG |

| Ack-check Function | NO |

| Max open angle | 180 |

| Closing speed adjustment | Spee1:180°-15° ; Speed2:15°-0° |

| Applicable temperature | -20℃-45℃ |

| Applicability | left open or right open door |

| Passed durability test | 500,000 cycles |

|

|

|

| Unit Weight | 2.1KG |

| Standard Package | 10PCS/carton |

| Carton Weight | 2.1KG |

| Carton Size | 47*33*19(cm) |

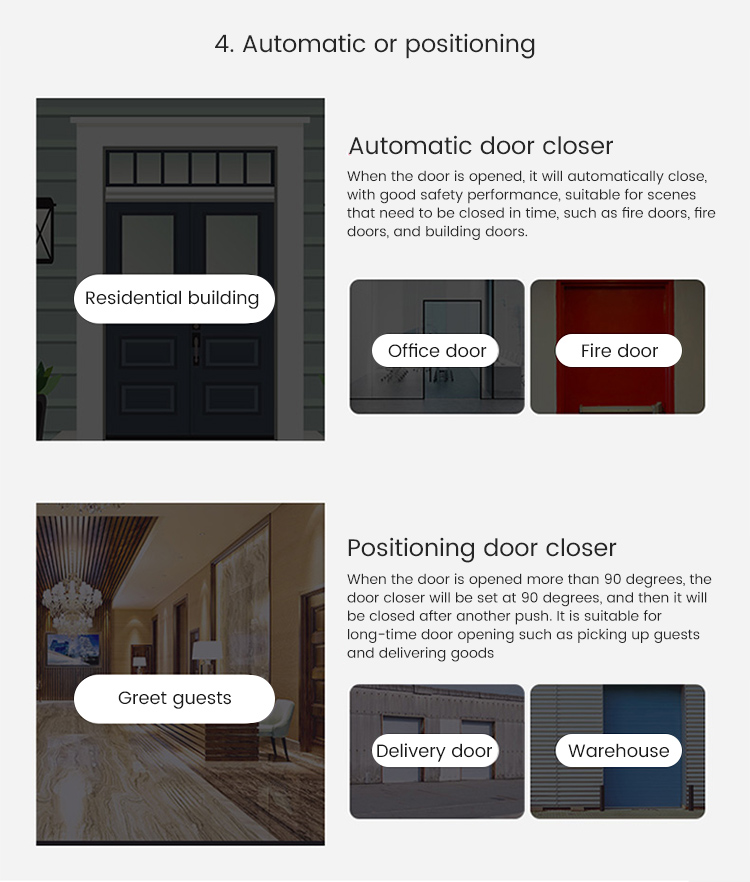

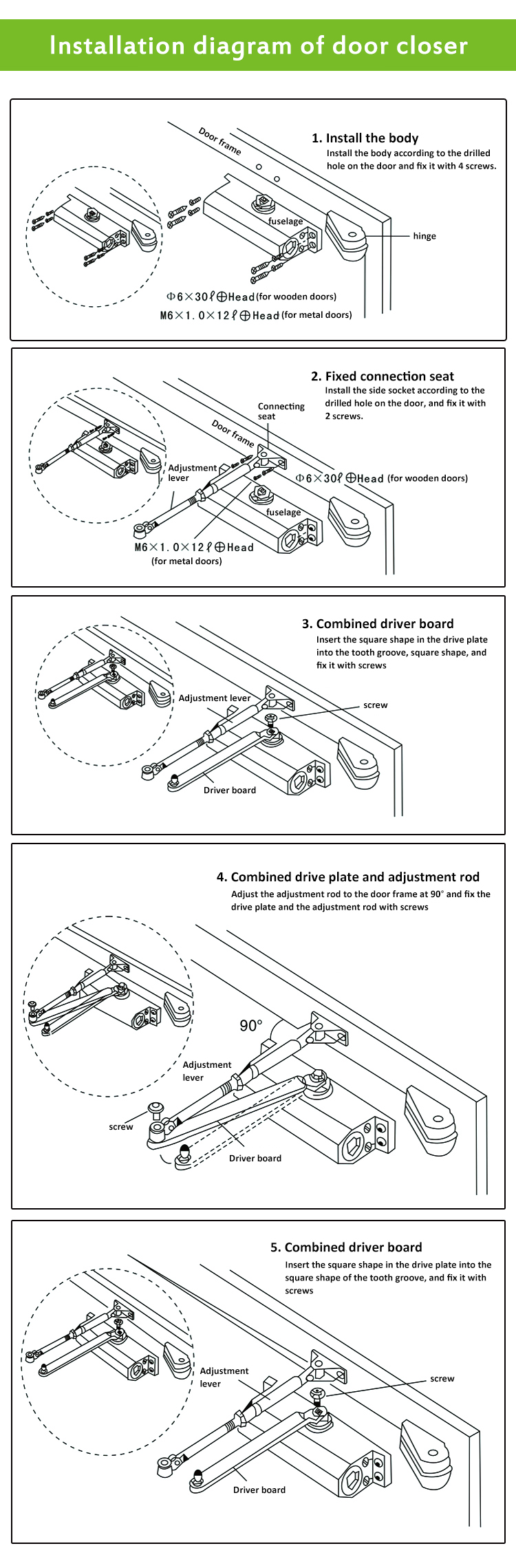

Installing a 100-150kg hydraulic automatic door closer on a wooden door requires careful preparation and step-by-step execution to ensure proper functionality and safety. Here’s a comprehensive guide to help you through the process: